Pylons, Towers & Telcom

Description

Works at heights on metallic structure include a wide range of cases such as works on high voltage pylons, cableway pylons, telecommunications antennae, metallic structures within industrial buildings and theatre structures. The access methods vary significantly depending on the type of structure, but they often have in common the need to use fall arrest systems which must be used for the progression, to then be integrated into the work positioning systems.

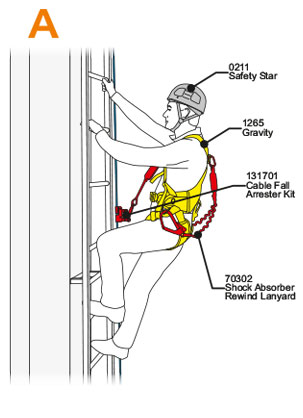

A – Vertical metallic structures (such as cableway pylons, wind farm turbine poles) are very often equipped with ladders for progression combined with a vertical anchoring cable on which cable fall arrest devices can be installed and which follows the operator during movement and intervenes to arrest any fall. For anchoring in the areas of the structure without the vertical cable, a double lanyard with an energy absorber must be used.

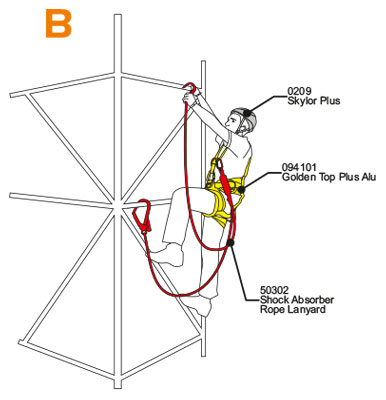

B – For progression on structures without anchoring devices, the operator can proceed anchoring himself directly to the structure (after verifying resistance) by means of a double lanyard with energy absorber and connectors suitable for the size of the structure.

C1 – After the ascent of the operator, a rope or severalropes can be secured on the summit of the structure, to which the operators can anchor themselves by means of appropriate rope fall arrest devices which allow vertical movement. This way subsequent ascent and descent operations are much safer and more efficient.

C2 – For positioning on the structure an adjustable positioning lanyard is recommended.

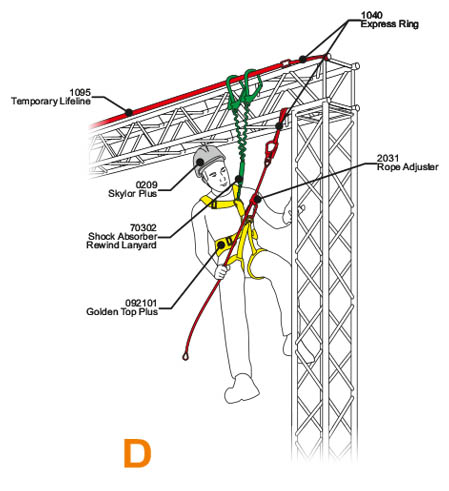

D – In case of horizontal, industrial or theatre metallic structures, progression can be carried out just the same by means of a double lanyard with energy absorber. To facilitate movement a temporary horizontal life line can be secured along the structure to which the lanyard is to be hooked. For work positioning purposes, an adjustable positioning lanyard is recommended.